Introduction:

Introduction:

Polyacrylic Acid (PAA) is a synthetic resin widely employed across various industries due to its remarkable properties. Also known as Carbopol, it serves as a key component in coatings, adhesives, inks, and other applications, contributing to enhanced durability, adhesion, and weather resistance.

Physical and Chemical Properties:

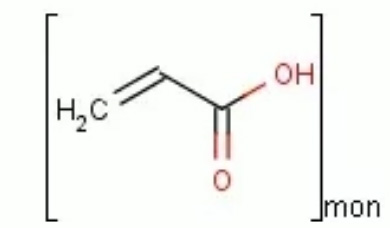

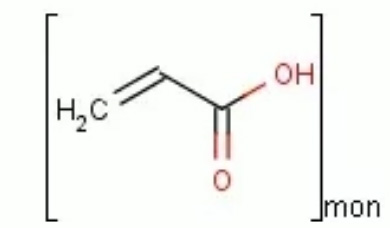

With a CAS number of 9003-01-4 and a molecular formula of (C3H4O2)n, PAA presents as a colorless or yellowish solid with good transparency and luster. It boasts excellent weather resistance, chemical stability, and corrosion resistance. PAA exhibits good adhesion and abrasion resistance, making it a preferred choice for numerous industrial applications.

Uses:

PAA finds widespread use in coatings, where it enhances impact resistance and durability. In adhesives, it serves as a key ingredient in various types, including hot melt adhesives and water-based adhesives, contributing to their adhesive properties. Additionally, PAA is utilized in the preparation of high-quality inks, imparting good fluidity and adhesion.

Preparation Method:

The preparation of PAA primarily involves free radical polymerization and ionic polymerization. In free radical polymerization, acrylic acid and acrylate monomers polymerize to form the resin. Ionic polymerization entails the reaction of acrylic acid with an initiator such as butyl lithium to generate lithium acrylate, followed by the addition of an active monomer to form PAA.

Safety Information:

While generally safe under normal circumstances, precautions should be taken during handling. PAA may cause skin and eye irritation upon contact, necessitating the use of protective glasses and gloves. Additionally, PAA exhibits low volatility but may emit harmful gases at high temperatures, highlighting the importance of maintaining adequate ventilation during operations.

In conclusion, Polyacrylic Acid (PAA) stands out as a versatile synthetic resin with a myriad of applications in coatings, adhesives, inks, and more. Its exceptional properties contribute to improved performance and durability across various industrial processes, underscoring its significance in modern manufacturing and materials science.

Home ≫ CCompany News

Home ≫ CCompany News

JIANGYIN TRUST INTERNATIONAL INC was established in 1996, dedicated to the production and export of water treatment chemicals, pesticides, and other chemicals. Our primary markets include Europe, South America, USA, Australia, Southeast Asia, and other regions.

JIANGYIN TRUST INTERNATIONAL INC was established in 1996, dedicated to the production and export of water treatment chemicals, pesticides, and other chemicals. Our primary markets include Europe, South America, USA, Australia, Southeast Asia, and other regions.